ХАРАКТЕРНАЯ ЧЕРТА

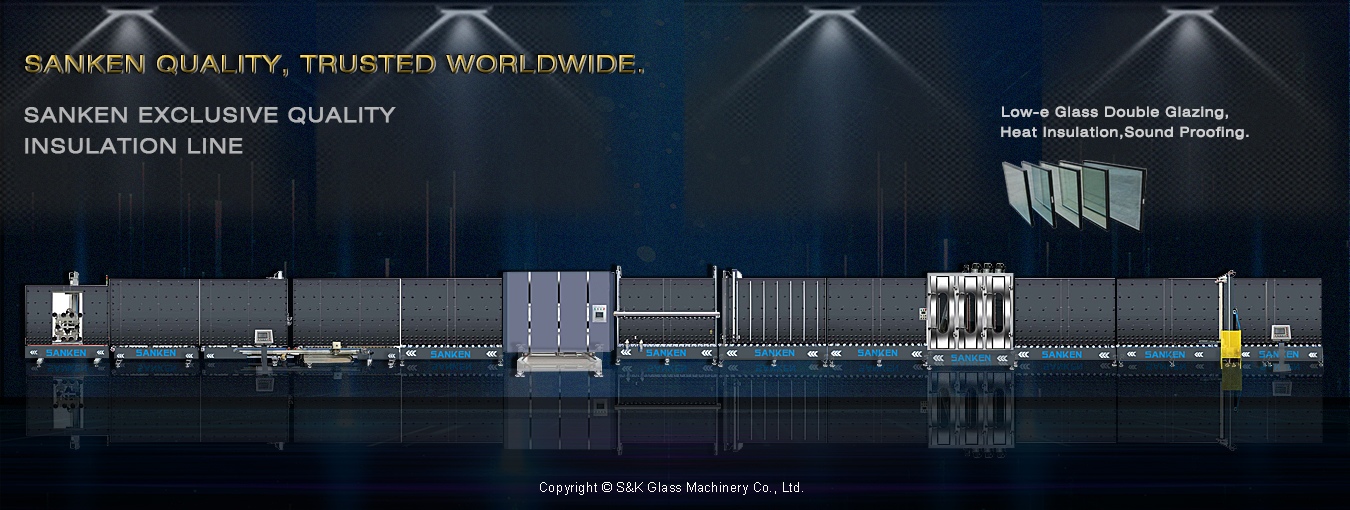

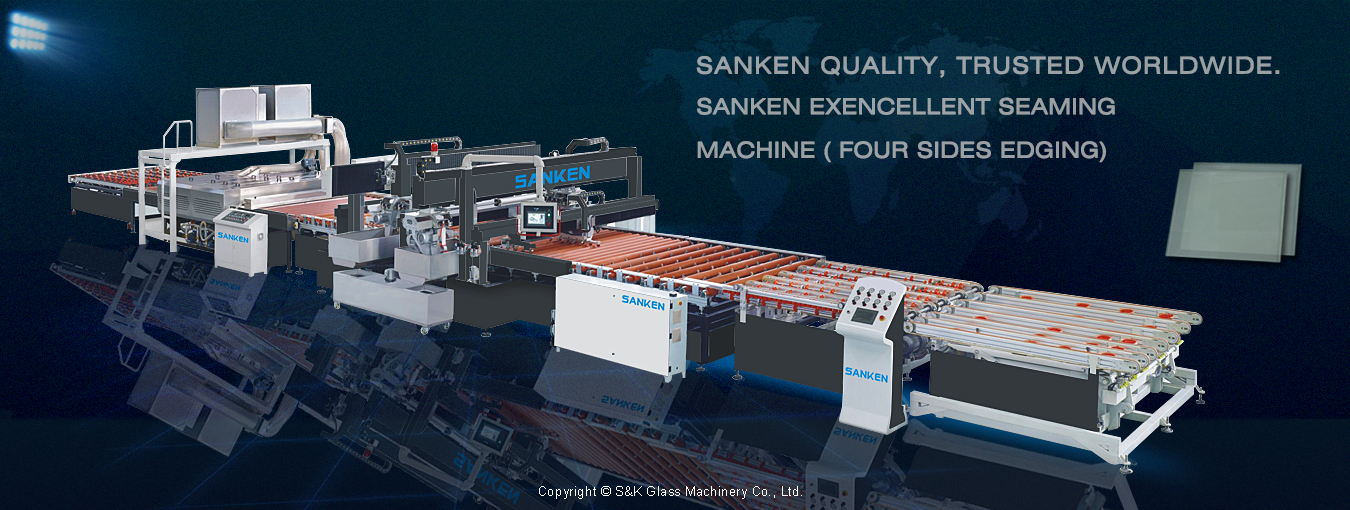

Автоматическая закаточная машина SANKEN занимает лидирующие позиции в отрасли глубокой обработки стекла. Мы производим эту автоматическую закаточную машину для стекла с использованием самых передовых технологий и материалов высочайшего качества. Автоматическая закаточная машина для стекла SANKEN обладает такими преимуществами, как высокая скорость окантовки, хороший эффект обработки, высокая стабильность, чрезвычайно низкий уровень отказов и простота обслуживания. Это одно из необходимого оборудования в области глубокой обработки стекла.

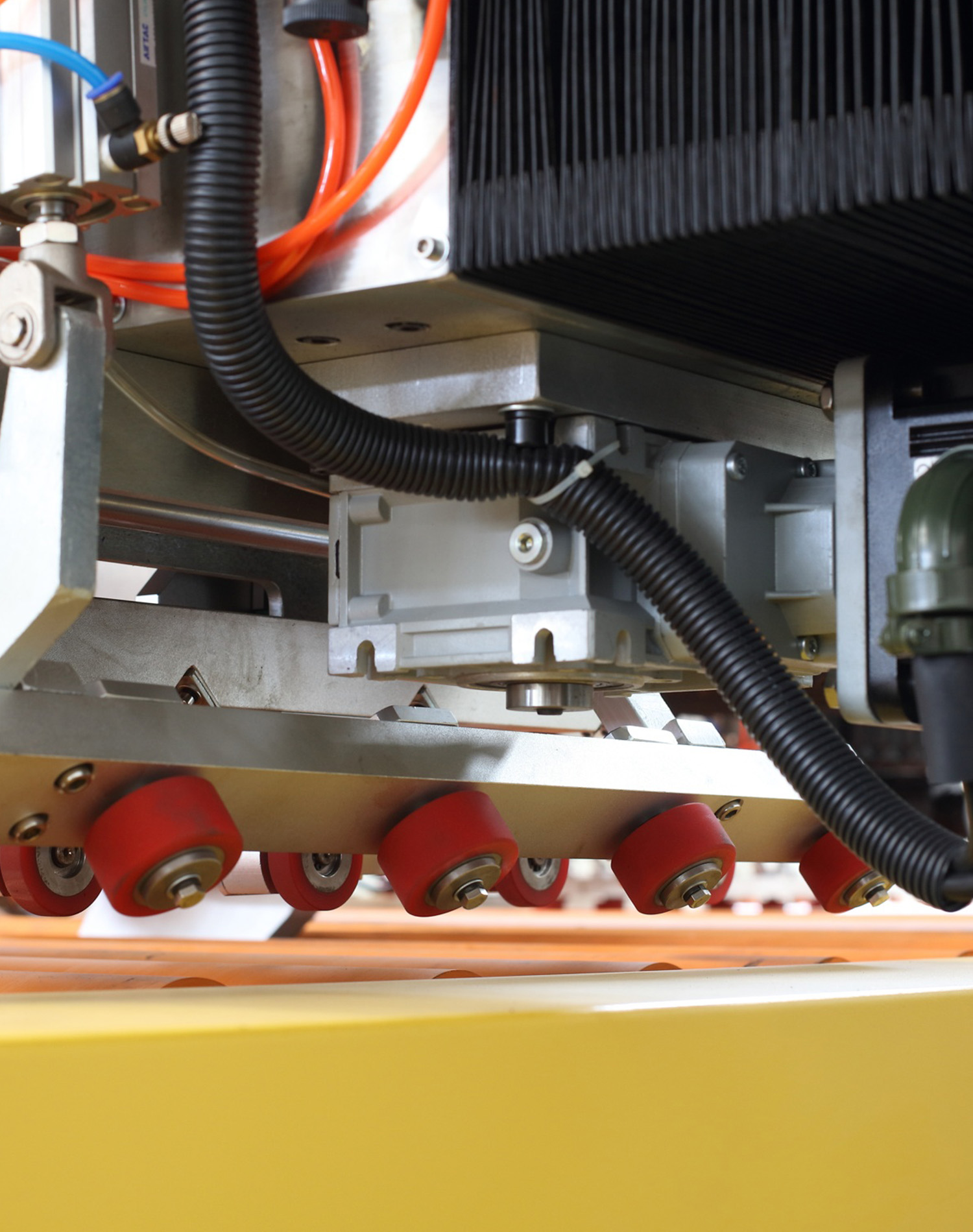

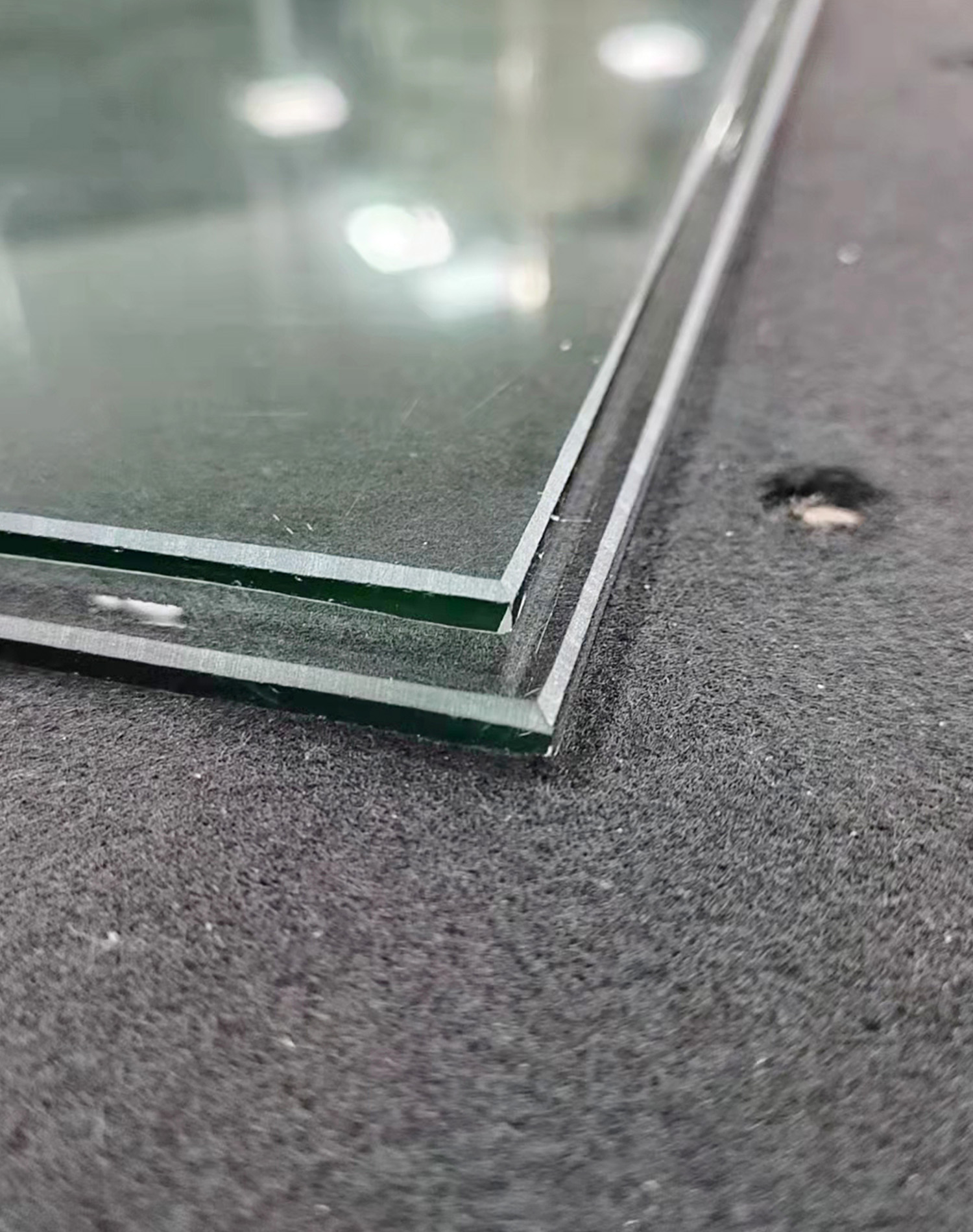

Основные компоненты автоматической закаточной машины для стекла состоят из секции загрузки стекла, секции шлифовки стекла и секции разгрузки стекла. Основной корпус автоматической закаточной машины для стекла изготовлен из высокопрочной кованой стали, долговечной и устойчивой к коррозии. Автоматическая закаточная машина для стекла приводится в действие серводвигателями, а операция может контролироваться с помощью сенсорного экрана ПЛК. Автоматическая закаточная машина для стекла SANKEN H имеет систему регулирования скорости преобразования частоты, которая может автоматически определять размер и толщину стекла разных размеров и толщины, а также имеет функцию автоматической компенсации для обеспечения наилучшего эффекта шлифования. Техническое обслуживание оборудования очень простое, например, автоматическая подача смазочного масла, автоматическая очистка стеклянной плиты и обеспечение отсутствия стеклянного шлака в стекле, чтобы гарантировать, что стекло не будет повреждено зазорами. Это очень полезно для эффективного производства и обработки стеклопакетов.

Автоматическая закаточная машина SANKEN занимает лидирующие позиции в отрасли глубокой обработки стекла. Мы производим эту автоматическую закаточную машину для стекла с использованием самых передовых технологий и материалов высочайшего качества. Автоматическая закаточная машина для стекла SANKEN обладает такими преимуществами, как высокая скорость окантовки, хороший эффект обработки, высокая стабильность, чрезвычайно низкий уровень отказов и простота обслуживания. Это одно из необходимого оборудования в области глубокой обработки стекла.

Основные компоненты автоматической закаточной машины для стекла состоят из секции загрузки стекла, секции шлифовки стекла и секции разгрузки стекла. Основной корпус автоматической закаточной машины для стекла изготовлен из высокопрочной кованой стали, долговечной и устойчивой к коррозии. Автоматическая закаточная машина для стекла приводится в действие серводвигателями, а операция может контролироваться с помощью сенсорного экрана ПЛК. Автоматическая закаточная машина для стекла SANKEN H имеет систему регулирования скорости преобразования частоты, которая может автоматически определять размер и толщину стекла разных размеров и толщины, а также имеет функцию автоматической компенсации для обеспечения наилучшего эффекта шлифования. Техническое обслуживание оборудования очень простое, например, автоматическая подача смазочного масла, автоматическая очистка стеклянной плиты и обеспечение отсутствия стеклянного шлака в стекле, чтобы гарантировать, что стекло не будет повреждено зазорами. Это очень полезно для эффективного производства и обработки стеклопакетов.

中文

中文

English

English

español

español

Français

Français

русский язык

русский язык

عربية

عربية